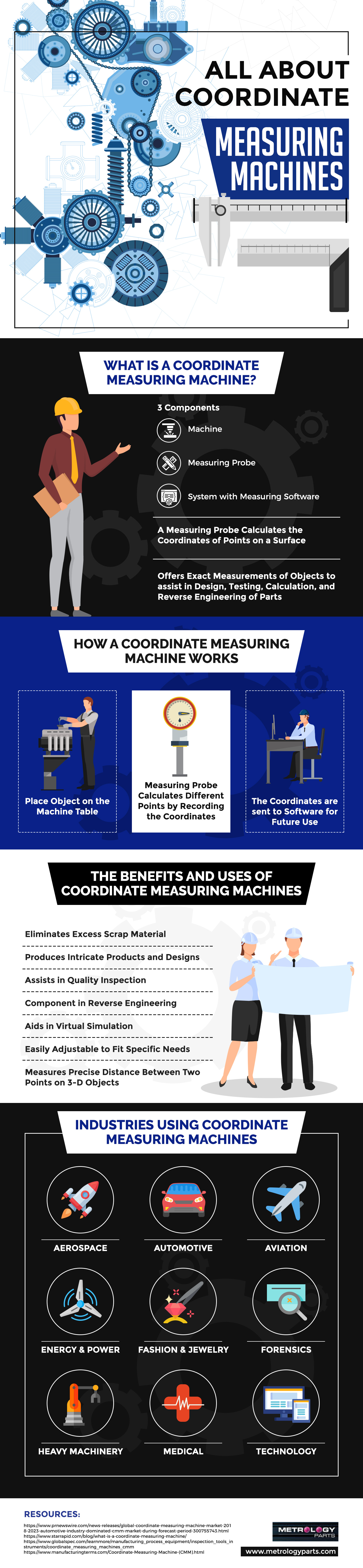

Coordinate measuring machines are used for a variety of purposes and benefit multiple industries. The components of measuring machines are the machine, measuring probe, and system with measuring software, and a coordinate measuring machine offers exact measurements of objects to assist in design, testing, calculation, and reverse engineering of parts. The process behind how a coordinate measuring machine works is an object is placed on a machine table, the measuring probe calculates different points by recording the coordinates, and the coordinates are sent to software for future use. A number of industries use coordinate measuring machines including aerospace, automotive, aviation, heavy machinery, medical, and technology. Take time to research and learn about how coordinate measuring machines function and are beneficial.

A coordinate measuring machine allows you to take a wide variety of accurate measurements. There are different options for these coordinate measuring systems. However, they all allow you to get an accurate measurement of an object's geometry on its X, Y, and Z axes. The main differences are with the probing system of the measuring machine. Read on to learn more about traditional CMMs and how they can benefit your workplace.

What a Coordinate Measuring Machine (CMM) Is

A CMM uses a touch-trigger, vision probe, or scanner to take a series of measurements on the surface of a three-dimensional object. They can be made from granite, aluminum, and other thermodynamic materials. Temperature changes expand and contract the machine's housing. Those changes are accounted for in the system's software. The machine has a software-based coordinate system. To take the measurements, it uses a range of contact and non-contact interactions with the probe heads.

Primary Components of a CMM

The primary components of bridge CMMs, traditional CMMs or Gantry CMMs include the CMM probes, a multi-sensor, air bearing, and handheld remote control. The CMM probes are controlled with movements of your hand or directions you input into the software. The software connects to your Wi-Fi, and it automatically updates with new algorithms. Machines with a touch-trigger probe, including the TP20 or TP200, are able to accommodate most of the parts you'd ever need to measure. If a part has a lot of points to be measured, and the SP25 scanning probe may be the best option for you.

Benefits of CMM Technology

Horizontal arm CMMs allow you to measure complicated surfaces of objects that would otherwise be difficult or even impossible to reach or measure. You can also use the machines to perform a CMM inspection. This is often done for quality control purposes. When you're working on a prototype or test part, the CMM machine representing all axes of measure is a cost-effective way to know if the part meets the client's specifications. The technology is also used to test the accuracy and precision of manufactured parts against design specifications. CMM machines can deliver repeatable results, which isn't always the case with measurements taken by a person. The machine takes the measurements in less time, and it can track them or feed them into your logging system for record-keepin